THE SNAPSHOT

Dalhousie researchers and their industrial partners have piloted the world’s first municipal-scale UV LED reactor for wastewater treatment. This groundbreaking innovation, currently disinfecting water in Eastern Passage, Nova Scotia, slashes energy use, curbs greenhouse gas emissions, and eliminates the toxic mercury bulbs that have long been a necessary evil in the industry, setting the stage for a revolution in how wastewater is treated worldwide.

THE CHALLENGE

Most of us give little thought to where our water goes once it swirls out of sight or how much it costs to make it safe again. But if you ask Halifax Water’s acting director of environment, health and safety, Dr. Wendy Krkosek, she says the expense of wastewater disinfection can feel draining — at least when compared to the technology Halifax Water is studying in collaboration with Dalhousie engineering researchers and their industrial partner AquiSense.

Halifax Water employee checks wastewater data. (Danny Abriel photo)

Unfortunately, for now, there’s not much choice. The gold standard for disinfection relies on ultraviolet (UV) light to destroy or deactivate harmful microorganisms like bacteria, viruses, and protozoa. During the final step of treatment, wastewater is bathed in a blast of UV light before returning to our waterways. It’s effective, but there’s a catch — the mercury vapor lamps that currently illuminate the process gulp energy, soil easily, and come with hefty price tags for maintenance and replacement.

“The bulbs produce a lot of heat, and in a wastewater system, you can imagine there's a lot of material in the water that builds up on them as a result, causing fouling,” says Dr. Krkosek.

“And so, there's a very large operation and maintenance cost in cleaning the bulbs. It's a significant burden on operations.”

Worse still, the mercury inside the bulbs is a potent neurotoxin that’s dangerous to both people and the planet. The UN Environment Programme’s Minamata Convention will put a stop to mercury mining by 2032, slamming the breaks on the supply needed by the industry. The European Union banned the use of the chemical element, only making an exception for wastewater treatment due to a lack of alternatives.

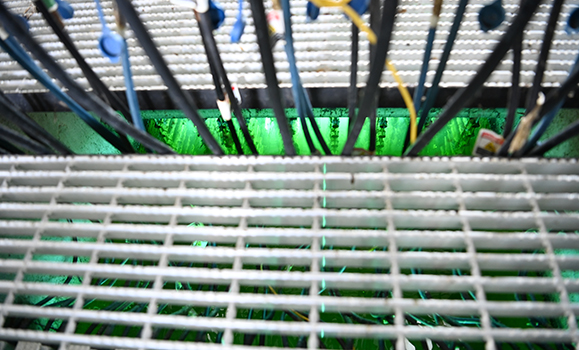

Glowing UV mercury bulbs disinfect but foul easily. (Danny Abriel photo)

But for utilities, permitted and desirable are two very different things. Responsibly disposing of mercury bulbs is costly and complicated. As a result, they often end up stockpiled, racking up storage costs, along with potential risks.

THE SOLUTION

You’re likely reading this story on a smartphone or monitor and staring directly at the answer Dalhousie researchers found to meet the cost and energy challenges of UV water treatment — light emitting diodes (LEDs).

These cheap, plentiful, tiny points of light make up our screens and much of our illuminated environment. They are also the light source that water scientists Drs. Graham Gagnon, Amina Stoddart and Sean MacIsaac have proven can replace the energy-hungry mercury vapor bulbs that dominate the industry.

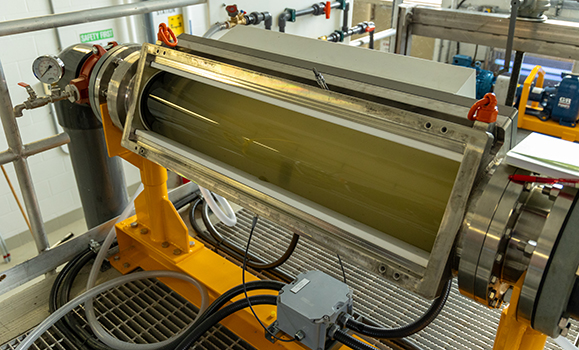

The advantage of UV LEDs extends beyond their affordability and the absence of mercury and enters the realms of chemistry and physics. Dr. Gagnon, director of Dalhousie’s Centre for Water Resources Studies, explains that, unlike mercury vapor bulbs, which emit light and heat in all directions, UV LEDs are far more disciplined. They direct light one way and radiate heat the other. This means that as wastewater flows past the thousands of tiny diodes in a UV LED reactor, it is bathed in pure, targeted UV light without the high temperatures that lead to the buildup of effluent that fouls traditional mercury bulb systems.

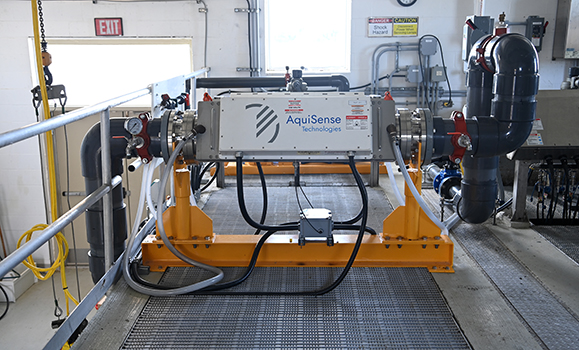

The AquiSense UV LED wastewater treatment reactor. (Submitted photo)

THE WORK

Already embraced by a handful of innovative water utilities for treating drinking water, UV LED technology had never been proven — much less trusted — to disinfect wastewater on the scale required by a municipality. But after years of experimentation and refinement of the science, Dr. Gagnon began to see a glimmer of potential.

It started in 2019, with a single-diode unit Dr. Gagnon took to Nunavut for field research — a modest start that sparked a growing fascination as the technology rapidly evolved. Now, UV LEDs are a key focus of an NSERC Alliance Advantage grant that brings his team together with AquiSense, the world’s largest supplier of UV LED water disinfection systems, Halifax Water and a coalition of public and private organizations.

With AquiSense already making rapid advances, scaling up systems to meet the needs of drinking water disinfection at municipal and industrial levels, Dr. Gagnon says he saw the need to explore a new area — wastewater.

He worked with the industry leader to adapt cutting-edge tech to Halifax Water’s systems, paving the way for the world’s first municipal-scale UV LED reactor for wastewater treatment. The Dal researchers worked with Halifax Water to bring the system to life, teaming up with the utility to install and operate it at its Eastern Passage wastewater treatment facility.

The reactor has been integrated into the utility’s infrastructure since January 2024, allowing it to function at a municipal scale over an extended period of time. Students collect samples working alongside Halifax Water employees and allowing researchers to closely study its efficiency, both in terms of its ability to disinfect water and the energy required to do it.

Inside of the AquiSense UV LED reactor. (Submitted photo)

Their findings, published in the most recent edition of the leading journal Water Research X, are extremely positive, proving for the first time the ability of a UV LED system to meet the needs of municipal water disinfection. In fact, Halifax Water’s Dr. Krkosek says the UV LED reactor is working so well that it’s difficult to know exactly how much power is actually needed for it to get the job done.

THE IMPACT

The goal now is to find the sweet spot for operating the reactor with the least amount of power and greatest volume of water to achieve full disinfection without wasting energy. But initial experiments already indicate that the UV LED system will require just a fraction of the energy consumed by traditional UV bulbs.

Dr. Gagnon, director of Dalhousie’s Centre for Water Resources Studies, led the project. (Danny Abriel photo)

“Our research shows that we are using energy much more efficiently and so that will be much better from a greenhouse gas emission standpoint. We don’t use any harmful chemicals, we consume less CO2, we consume less space, and we can deliver the same volume of water with at least the same quality, if not better,” says Dr. Gagnon.

After comparing the costs associated with traditional mercury bulb systems, Dr. Gagnon says, “Something of a similar capacity with UV LEDs would significantly reduce capital investment and then from an operational and maintenance perspective, the savings made over its lifetime will be substantial.”

Cost and efficiency aside, there is also the urgent need to stop the flow of mercury laden bulbs into stockpiles around the world. With the lack of alternatives no longer a problem, it’s expected the EU and other jurisdictions will strike exceptions for mercury in the wastewater industry, casting their eyes to Eastern Passage for solutions — the somewhat unlikely home of the industry’s new state-of-the-art.

“This the only place in the world that is doing it. We’re hearing from many municipalities that are keen to know more about what we’ve proven is achievable,” says Dr. Gagnon.

Dr. Krkosek at Halifax Water agrees that things are moving quickly.

“In the next few years, we expect to see this UV LED technology used at full scale, and it could be transformative for Halifax Water and the entire industry,” she says. “We are proud to be at the forefront of this research with Dr. Gagnon and Dalhousie and to know that our commitment to innovation will create greater operational efficiencies that will ultimately benefit our customers.”