News

» Go to news mainDalhousie Honours Dr. Ted Hubbard for Excellence in Educational Innovation

If you’re a Dalhousie Mechanical Engineering student, you’ve certainly heard of Dr. Ted Hubbard’s 3D printing course. In fact, the class is so popular, it fills up in under 60 seconds each year.

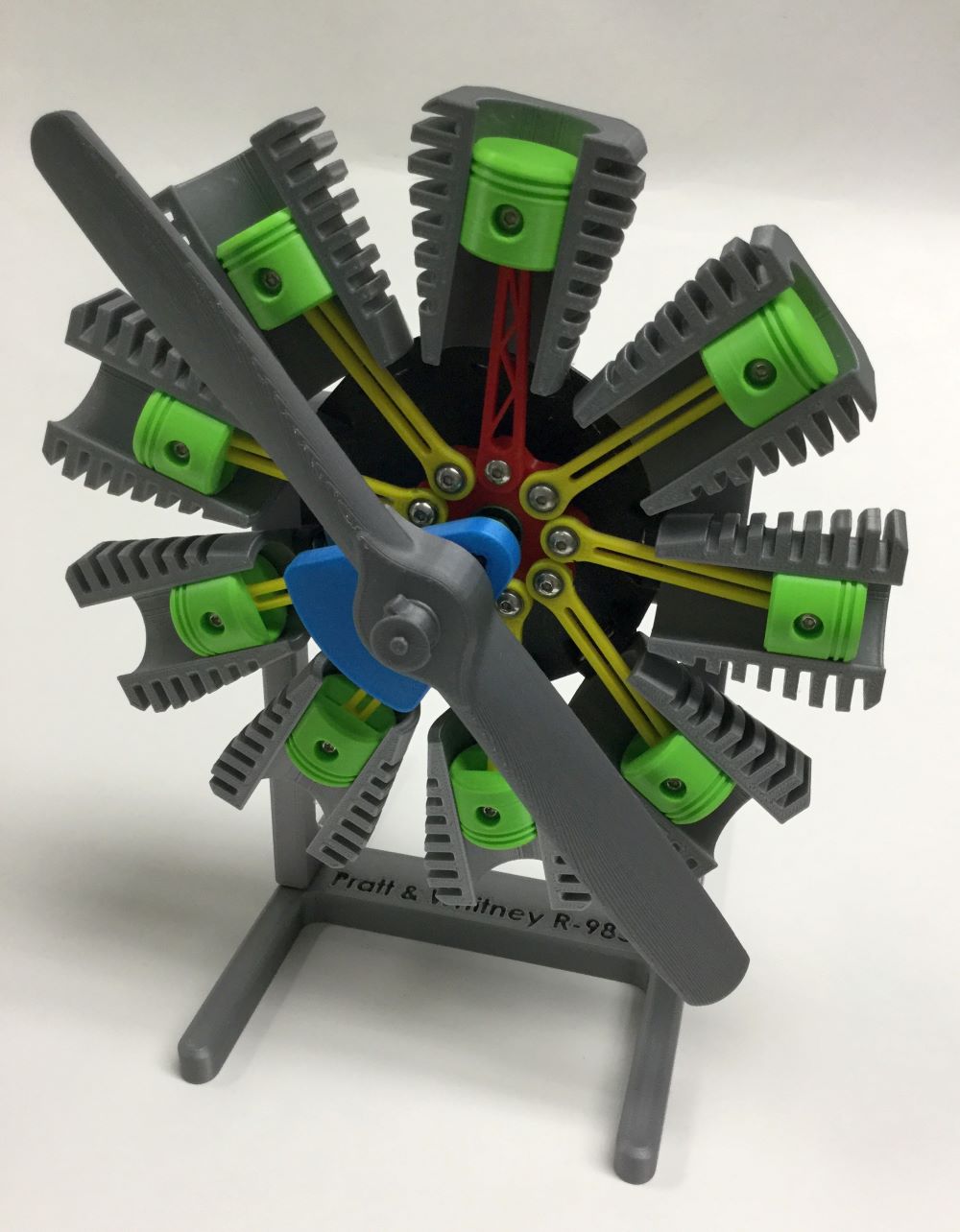

The course gives students the opportunity to gain hands-on learning experience in design, testing, and machine building. Venture through the halls of the Emera Idea Building on Sexton campus, and you’ll come across a glass display showcasing some of the innovative designs created by students in the course. It’s a shining testament to why Dr. Hubbard was recently honoured by Dalhousie University with the Academic Innovation Award.

Presented by Dal’s Centre for Learning and Teaching, the award recognizes leading instructors on campus who play a pivotal role in creating exceptional learning experiences for their students.

Since joining Dalhousie’s Department of Mechanical Engineering in 1995, Dr. Hubbard has consistently provided hands-on learning experiences. It started with the now-famous KitchenAid® stand mixer lab, where students disassembled and reassembled a KitchenAid mixer to gain a firsthand look at its mechanical components. From there, he designed courses based around the use of cordless drills, bike computers, fish scales, and more. These “hands-on” learning techniques allow students to not only touch and feel real mechanisms, machines, and manufacturing processes but also critically evaluate them to gain a deeper understanding of their underlying principles.

Over the years, Dr. Hubbard's teaching style has been praised by colleagues and students and has significantly inspired and influenced the Mechanical Engineering curriculum at Dal. However, his impact extends beyond the new tools and gadgets he introduces to the class. His influence on the Faculty is greatly enhanced by his approach to teaching life lessons, such as dealing with failure. In the world of engineering, where most designs fall short before they succeed, he teaches students how to embrace and overcome challenges in the creative process.

So, who is the man behind these innovative teaching approaches? Get to know the Faculty of Engineering’s Dr. Ted Hubbard in this short Q&A.

1. How does it feel to be recognized for your innovative methods of teaching?

Hands-on experiences are harder to make happen, and there are many people who make it work: from technicians who build new devices, to TAs who show them off, to Heads and Deans willing to find the money to pay for something new for students.

2. Where did you first come up with the concept of the KitchenAid Mixer lab?

We had always wanted some device that students could disassemble and (hopefully) put back together. But most items today are throwaway; most things are not meant to be taken apart. One of the few types of things still worth repairing are appliances. After a bit of searching, KitchenAids just have the most moving parts and the best repair manuals.

3. Why are these hands-on opportunities so important to student learning?

Unfortunately, many students now arrive at university with less hands-on experience than students from, say, 20 years ago. Our current students are very computer savvy, but it has come at a physical cost. Many students lack the basic grounding and hands-on experience in mechanical things that we, as engineers, need. I tell my students, "You are going to lay hands on everything we talk about," and for some, it is the first time. Not all engineers make things, but we all deal with made things.

4. As someone who is consistently coming up with innovative ways to engage students, what can they expect to see in your courses in the next few years?

What's next? Probably a bit of destruction. Students will break things. It is important for students to see how things fail (safely) and learn what causes mechanical failure and how to delay/subvert/avoid that failure.

Recent News

- Dalhousie Honours Dr. Ted Hubbard for Excellence in Educational Innovation

- Empowering youth and transforming communities: Celebrating International Women in Engineering Day

- Hydrogen Applications Research Lab Tour

- Unlocking the power of green hydrogen

- Deputy Prime Minister Freeland Champions Federal Research Investments at Dalhousie's Water Quality Lab

- Dalhousie FSAE electric vehicle electrifies at New Hampshire Motor Speedway

- Engineering alumni inducted into the Tigers Hall of Fame

- Alum honours engineering professor Corinne MacDonald's impact as a role model and mentor through gift