News

» Go to news mainUnlocking the power of green hydrogen

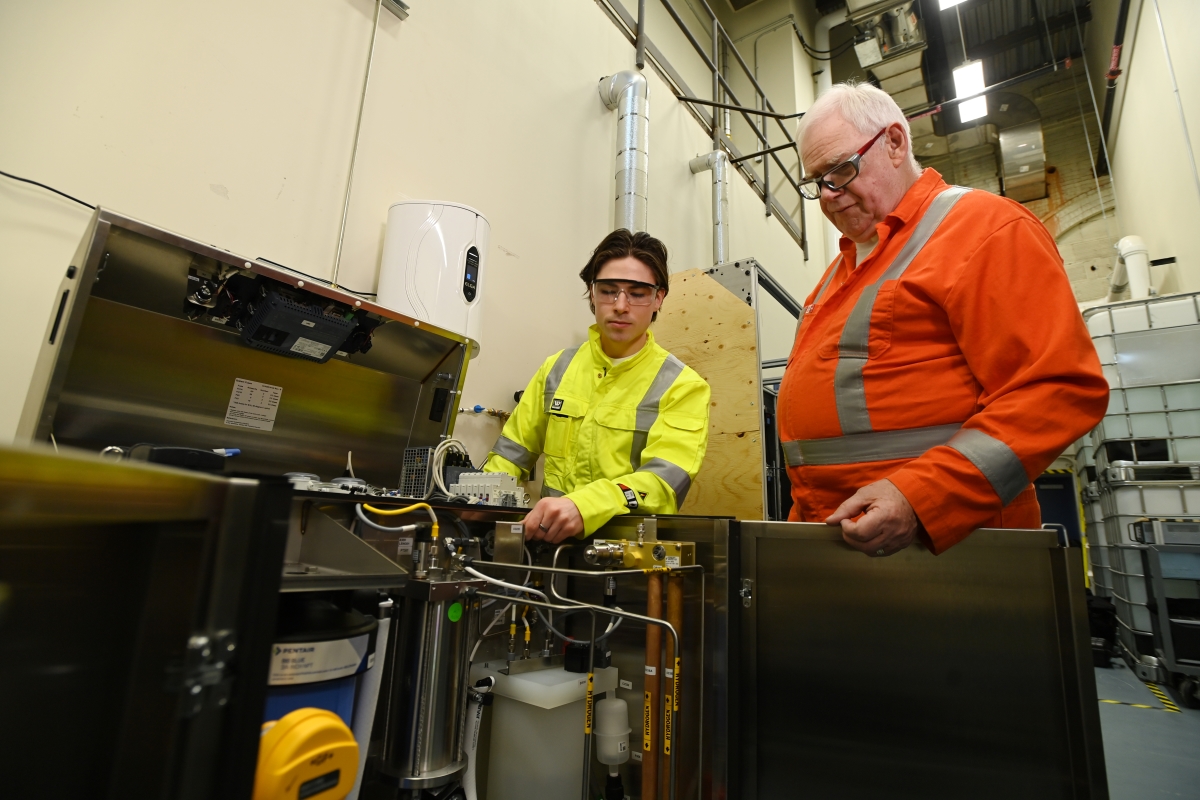

Standing amongst an array of appliances, Dalhousie Engineering PhD candidate, Theodore Street adjusts the controls on a gas stove and watches as the blue flame begins to burn. This particular stove is running on a blend of natural gas mixed with 5 per cent hydrogen. It’s one of a dozen different appliances that will be tested in Dalhousie’s new Hydrogen Applications Research Laboratory.

In collaboration with local energy provider Eastward Energy, the lab will test the limits of blending hydrogen into Eastward Energy’s natural gas system as well as the use of hydrogen-enriched natural gas in household appliances.

Eastward Energy has contributed $200,000 through an in-kind donation to support Dalhousie researcher Dr. Michael Pegg and his team in the Department of Process Engineering and Applied Science as they investigate low-carbon solutions for its distribution system, including the distribution of hydrogen-enriched natural gas. The partnership could assist Nova Scotia in its efforts to achieve net-zero greenhouse gas emissions by 2050.

Nova Scotia’s Green Hydrogen Action Plan, released in December, lays out guidelines for government and industry in the province in the development of green hydrogen — an alternative clean energy source.

What is green hydrogen?

While traditional methods for producing hydrogen use fossil fuels and emit greenhouse gases, green hydrogen is produced using renewable electricity and when it is burned emits only water and heat.

“Whenever you burn hydrocarbon flames such as methane/natural gas, oil, or anything with carbon in it, it produces CO2, which is a greenhouse gas. If you burn hydrogen in air, you don’t produce any CO2,” explains Street. From undergrad co-op programs to PhD candidates, Street is one of several students working side by side on this ground-breaking initiative.

Within the lab, Street points out several different types of appliances designed for natural gas including water heaters, a gas fired barbecue, gas stove, patio heater and more.

“We are going to be testing appliances that haven’t been tested before, and we’re looking primarily at operability limits” he says. Their team is ready to push the boundaries, searching for that “sweet spot” where the most hydrogen can be seamlessly integrated into the natural gas network without disruption or consequence to daily lives.

Testing hydrogen blends

They’ll start with a modest 5 per cent hydrogen blend, monitoring factors such as appliance temperatures and gas compositions to ensure everything runs smoothly. Slowly, they plan to increase hydrogen levels, pushing appliances to their limit. The goal is to find that balance where efficiency meets safety.

“We are standing here by a water boiler that would be used for underfloor heating or baseboard radiators,” says Street as he points out a row of boilers sitting along the back wall of the lab. “Previously published literature says there’s quite a wide range depending on the unit. Anywhere from 10-90 per cent hydrogen can be mixed in,” he continues. “So we have to test all sorts of different types of boilers and water heaters.”

While innovative, the research comes with many challenges. Hydrogen, for example, with its high flame speed, presents unique problems.

“One of the biggest issues with hydrogen and natural gas is that at really high blends sometimes the flame can be unstable,” says Street. “Hydrogen flames are a little bit hotter and they sit a little bit closer to the burner tip. If you turn off the burner, sometimes the hydrogen flame can travel back into the burner tip.”

That causes something they call flashback; a sudden pop which could signal trouble.

“Flashback is mostly a concern when you have a pre-mixed fuel air mixture. If you have air and fuel and the flame flashes back, it can flash back for as long as there’s air and fuel and it could cause detonation,” says Street. “For most natural gas appliances, it wouldn’t flash back that far because it’s not pre-mixed. The air is injected into the appliance burner quite late. But for modern high-efficiency boilers and water heaters they use pre-mixed burners which are more prone to flashback. That’s an area we’re very interested in researching”

As the lab continues blending hydrogen with natural gas one appliance at a time, Street is excited to play a role in such a transformative initiative.

“What interests me about this is the chance to focus on research that actually makes a difference in the here and now in the world,” he says. “The research that is being done on climate change is amazing, but so much of it won’t be seen until five, ten years down the road. What we really want to do is to do something right here, right now that can lower emissions.”

Recent News

- DalSolutions: Reinventing repair to keep Canada’s Navy mission ready

- Engineering Young Alumni Reception

- Students scale new heights with Toronto tower pitch

- Dalhousie Students Develop Automation Tool for Irving Shipbuilding

- 2025 Capstone Poster Expo

- Dalhousie Engineering Students Lead the 2025 Canadian Engineering Competition

- ‘A painless flash of light’: Biomedical Engineering student wins 3 Minute Thesis

- Sparking a Passion for Indigenous Engagement in Engineering