Bioprocess Engineering Research Group

- Research

- 2021-2026 Strategic Research Plan

- Research Laboratories, Groups, and Facilities

- Agricultural Soil and Water Studies Laboratory

- Atlantic Canadian Pasture Research Group

- Atlantic Soil Health Lab

- Genomics Unit

- Aquaculture

- Bio-Environmental Engineering Complex

- Canadian Centre for Fur Animal Research

- Christmas Tree Research Programme of Canada

- Ecophysiology Research Group

- Edible Horticulture Research

- Entomology Research Laboratory

- GeneNovaS

- Green Infrastructure Performance Laboratory

- Greenhouse Gas Lab

- Innovative Waste Management

- Maple Research Program

- Marine Bio-products Research Laboratory

- Needle Retention Research

- Organic Agriculture Centre of Canada

- Potato Consumer Research Initiative

- Potato Molecular Biology & Genomics Lab

- Precision Agriculture

- Processing Carrot Research Program

- Rhubarb Research Program

- Rural Research Collaboration

- The Farm

- Food Bioactives Research Program

- TREEhouse

- Bioprocess Engineering Research Group

- aquaculture centre

- Biofluids and Biosystems Modelling Lab

- Wild Blueberry Research Centre

- Industry

- Research News

- Our Researchers

- Information for Researchers

- McCain Postdoctoral Fellowships

- Undergraduate Student Research Awards

We’re taking charge of cutting edge technologies to make good food even better!

Mission Statement

Our mission is to help farmers to bridge the gap in post-harvest management of fresh produce in a fast-paced technological environment by providing knowledge dissemination, technological support and extension services.

Our vision is to bring our technological developments to farmers, industry and consumers to rebuild trust between researchers and community.

Through market-driven research, consumers tell us what needs to be designed. We will deliver:

- Innovative food and bioprocessing technologies

- Innovative process developmentI

- Innovative product development

Our motivation

Ultimately, we are motivated by the drive to make good food even better. Our work contributes to making better food technologies for producers resulting in better food for everyone. We are researching and developing new technologies to:

- evaluate food quality during processing

- extend the shelf-life of natural foods such as blueberries, grapes and apples.

- preserve and/or increase the health benefits of fruits and vegetables.

Funding Agencies

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Projects

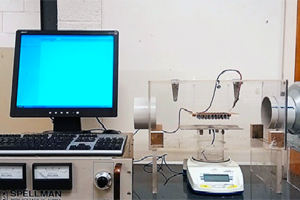

Electrohydrodynamic Technology (EHD)

Electrohydrodynamic drying is a novel method of non- thermal processing. The drying can be carried out using either AC or DC high voltages. The thermodynamic considerations regarding the lowering of temperature under EHD drying include rapid rates of evaporation and exothermic interaction of the electric field with a dielectric material. Multi-point and plate electrode systems are efficient in accelerating drying of agricultural materials. Compared to hot air (convective) drying systems, EHD drying systems offer lower production costs along with superior quality in terms of physicochemical properties such as colour, shrinkage, flavour, and nutrient content. Compared to convective and freeze-drying, EHD drying systems, given their simpler design and lesser energy consumption, show great potential for bulk and industrial drying applications. (source: EHD Drying—A Concise Overview).

This is a part of ongoing research project “Biorefinery of Grape Pomace” (2015-2016), funded by Nova Scotia Department of Economic Development, InnovaCorp Early Stage Commercialization Program (ESCF).

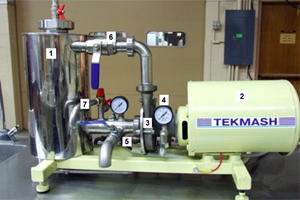

Hydro thermodynamic Processing (HTD)

Hydrothermodynamic technology (HTDT) uses the physical phenomenon of cavitation to provide quick heating, blending and pasteurization at the same time. It is a new technology that can be successfully used for processing any number of fruits, berries, vegetables and beans.

HTDT works on the principle that moving fluid induces local turbulence and multi-phase cavitation bubbles while going through the obstacle with disturbing streams of the liquid. The collapsing of these cavitation bubbles creates local shear forces and local pressure. This released energy leads to increases in the temperature of the moving fluid and results in crushing and homogenizing of the product into very fine particles with minimum quality degradation.

Advantages of HTD technology

1. Uniform volumetric heating of the product without direct heating

2. Reduced high-temperature oxidation due to no contact with oxygen during processing

3. Prolonged product shelf-life due to pasteurization

This is a part of ongoing research project “Development of Innovative Food Products, using Cavitation Technology: Quality and Safety Aspects” (2013-2017), funded by Agriculture and Agri-Food Canada, GFII. Industry partner PEI Berries Ltd. www.peiberries.com, collaborators:

Dr Lihua Fan (Kentville Research and Development Center, NS http://www.agr.gc.ca/eng/science-and-innovation/research-centres/atlantic-provinces/kentville-research-and-development-centre/?id=1180623750202

Dr Bohdan Luhovyy (Mount Saint Vincent University, Department of Applied Human Nutrition http://www.msvu.ca/en/home/programsdepartments/professionalstudies/appliedhumannutrition

Porosity Evaluation by Computer Vision

Porosity is one of the most important indicators of food texture and microstructure. Depending on the processing technology, food has open and closed pores, distributed randomly within material. Porosity can be estimated from either direct measurement of volume and mass or mathematical models. Mathematical models allow prediction of total porosity. Models for separate evaluation of open- and closed-pores porosity were recently developed in our lab. The goal is to develop remote imaging for real-time porosity evaluation in the process of drying.

This is a part of collaborative research with Dr Min Zhang (School of Food Science and Technology, Jiangnan University, Wuxi, China) “Highly Efficient Food Drying by Microwaves”, funded by MITACS (Mathematics of Information Technology and Complex Systems) https://www.mitacs.ca

Accomplished Projects

2015 Innovative Drying Technology for the Production of Appassimento Wine. NSERC Engage. Industry partner Luckett Vineyard Ltd. http://luckettvineyards.com

2014 Thermal Imaging of Plant Stress Response. NSERC Engage. Industry partner Acadian Seaplants Ltd. www.acadianseaplants.com

2013-2015 Development and Functional Characterization of Pulse Flour-Based Snack Products. NSERC Collaborative Research and Development. In collaboration with Dr. Luhovyy, Mount Saint Vincent University.

2008-2015 Multi-Spectral Imaging of Food Quality in Thermal Processing. NSERC Discovery Grant (Individual)

2012-2013 Development and Commercialization of Portable Harvester for Small & Medium Scale Berries Farmers. Innovation PEI, Development & Commercialization Fund. Industry partner PEI Berries Ltd. www.peiberries.com

2011-2012 Development and Commercialization of Innovative Natural Food Products from PEI Berries. Innovation PEI, Development & Commercialization Fund. Industry partner PEI Berries Ltd. www.peiberries.com

2010-2011 On-Farm Strawberry Processing. Nova Scotia Department of Agriculture, Technology Development Program. Industry partner Riverbreeze Farm Market. www.riverbreeze.info

2010-2011 Development of Value-Added Technology of Blueberry Pomace Processing. Nova Scotia Department of Agriculture, Technology Development Program. Industry partner Van Dyk Health Products Ltd. https://vandykblueberries.ca

2010 Development of Blueberry-Based Health-Promoting Foods. Prince Edward Island Department of Agriculture, Agri-Innovation Program. Industry partner PEI Berries Ltd. www.peiberries.com

2009-2010 Value-Added Fruit/Berry Processing Technology. Nova Scotia Department of Economic Development, InnovaCorp ESCF Program.

2009-2010 Nanotechnology of Blueberry Food Processing. Nova Scotia Department of Agriculture, Technology Development Program. Industry partner Atlantic Bioventure. www.perrenia.ca

2009-2010 Computer Vision Technology for Fruit Quality Processing (together with V.Rupasinghe). Nova Scotia Department of Agriculture, Technology Development Program. Industry partner Noggins Corner Farm. www.nogginsfarm.ca

2008-2012 The Physiological Mechanisms of Needle Abscission in Root-Detached Balsam Fir (together with R. Lada, and C. Caldwell). NSERC CRD. Industry partner Christmas Tree Council of Nova Scotia. http://ctcns.com

2008 Thermo Vision Imaging System for Bio-Environmental Management. NSERC Research Tools and Instruments Category I.

2008 Innovative Imaging Technologies for Bio-Environmental Management. Canada Foundation for Innovation (CFI), Leaders Opportunity Fund.

2008 Development of Imaging Technology for Water Management and Efficient Crop Production. Nova Scotia Water Expansion Program AAFC. Industry partner Horticulture Nova Scotia www.horticulturens.ca

2007-2008 Imaging Systems for Bio-Environmental Applications. Nova Scotia Department of Agriculture

2007 Computer Vision Applications for Agri-Food Industry. NSERC PDF Grant to Visiting Scientists to Governmental Laboratories. Harrow Research and Development Centre (AAFC). http://www.agr.gc.ca/eng/science-and-innovation/research-centres/ontario/harrow-research-and-development-centre

2002-2006 Optimization of Quality in Ginseng Drying using Computer Vision System. NSERC Industry funding. Industry partner Ontario Ginseng Growers Association. http://www.agriguide.ca/organization/ontario-ginseng-growers-association

Benefits

Our innovations in food engineering provide benefits to farmers, industry and consumers.

- Farmers in Nova Scotia and around the world can reduce spoilage of fresh fruits due to innovative post-harvest management and value chain development. We are developing low-cost solutions, logistics and technologies to mitigate multiple problems of post-harvest management and extend shelf life of fresh fruits and vegetables.

- Industry can keep pace with the emerging developments in technology. Our knowledge dissemination and extension services bridge the gap between expertise and implementation.

- People can enjoy 100% pure fruits and vegetables out of season. With our food processing technology, fruits and vegetables can be preserved without adding any preservatives and compromising their health benefits.

Team

Alex Martynenko, Lead Researcher

Dr. Alex Martynenko is professor in Bioelectronics and Bioinstrumentation at the Dalhousie Faculty of Agriculture. Working on the border of biological science and engineering, he is developing innovative technologies for value-added food processing.

Dr. Alex Martynenko is professor in Bioelectronics and Bioinstrumentation at the Dalhousie Faculty of Agriculture. Working on the border of biological science and engineering, he is developing innovative technologies for value-added food processing.

Working in University of Guelph, he developed advanced technology of “gentle” ginseng drying. This technology, developed for Ontario ginseng growers, significantly decreased energy requirements and improved quality of ginseng drying. In 2007 he established a framework for a strong and innovative Imaging Research Program in Dal-AC with emphasis on two major research themes: (i) multi-spectral imaging of food quality parameters, (ii) effect of processing technologies on food quality.

Theme (i) is based on quantification of food quality parameters, using morphological, colour and textural attributes of digital images (Martynenko, 2006). This research is supported by NSERC Discovery Grant “Multi-Spectral Imaging of Food Quality”, NSERC RTI and CFI Leadership Opportunities Fund. New knowledge about measurable attributes of food quality in the spectral range from 0.2 to 14.4 mm, expected from this study, will improve understanding of underlying phenomena of food quality degradation.

Theme (ii) is focused on the development of “gentle” food processing technologies minimizing quality degradation (Martynenko et al., 2015). Dr. Martynenko’s research group is developing innovative HTDT technology for processing of fruits and berries into nutritional pastes. HTDT is based on simultaneous blending, homogenizing and pasteurization in liquid viscous flow. This technology is relatively new, so research efforts are focused on effects of HTDT on food quality, microstructure and bioavailability.

Through his career, Dr Martynenko has successfully managed a number of research projects related to the development of innovative value-added processing technologies. He successfully completed nineteen research projects, including three international; presented results of research work in peer-reviewed scientific journals (62), and on international conferences (46). He is author and co-author of four books and ten patents, requested author of two reviews in Drying Technology and an instructor for industry-oriented short courses.

Yougui Chen, Research Assistant

M.Sc. (Human Nutritional Sciences), University of Manitoba

B.Sc. (honors), Dalhousie University

Yougui worked on food dehydration and computer vision analysis of food quality during food processing as an undergraduate research assistant with Dr. Alex Martynenko in 2012 at Dalhousie. For his graduate work at the University of Manitoba, he studied the antioxidant properties of polyphenols from canola by-products in food and in vitro cellular models. He graduated with his M.Sc. in Human Nutritional Sciences in 2015. He joined Dr. Alex Martynenko’s lab in April of 2015 as a research assistant. Yougui brings his food chemistry and nutrition background to the Bioprocessing Engineering Research Group and is now working on a novel food processing technology, hydrothermodynamic (HTD) processing for developing an innovative form of foods with higher nutritional values.

Yougui worked on food dehydration and computer vision analysis of food quality during food processing as an undergraduate research assistant with Dr. Alex Martynenko in 2012 at Dalhousie. For his graduate work at the University of Manitoba, he studied the antioxidant properties of polyphenols from canola by-products in food and in vitro cellular models. He graduated with his M.Sc. in Human Nutritional Sciences in 2015. He joined Dr. Alex Martynenko’s lab in April of 2015 as a research assistant. Yougui brings his food chemistry and nutrition background to the Bioprocessing Engineering Research Group and is now working on a novel food processing technology, hydrothermodynamic (HTD) processing for developing an innovative form of foods with higher nutritional values.

Dandan Wang, Masters Student

Dandan Wang, Masters Student

B.Sc (Honors) in Integrated Environmental Management, Dalhousie University

Research Assistant in Dr. Martynenko’s lab with TA-XT Texture Analyzer (2013/2014)

Martynenko A., Wang D. (2015). Separate evaluation of open-and closed-pores porosity. ICEF12 International Congress on Engineering and Food, Quebec, Canada, June 14-18, 2015 (poster presentation accepted in February 2015).

Martynenko A., Wang D. (2015). Instrumentation for measurements of open- and closed- pores porosity 2015 ASABE Annual International Meeting, New Orleans, USA, July 26-29, 2015, (poster presentation accepted in February 2015).

2014/2015 Supplemental Nova Scotia Graduate Entrance Scholarship

International Students Scholarship at Dalhousie University (2014/2015)

Weiwei Zheng, Research Assistant

2013-2015 B.Sc (Agriculture) in Integrated Environmental Management, Dalhousie University

2013-2015 B.Sc (Agriculture) in Integrated Environmental Management, Dalhousie University

Since September 2015 enrolled in M.Sc. (Environmental Engineering) in Toronto University.

Publication:

Martynenko, A. & Zheng, W. (2015). Electrohydrodynamic drying of apple slices: energy and quality aspects. Journal of Food Engineering 168(1), p. 216-222

Email: Weiwei.zheng@dal.ca

Nicolas Riaud, Research Assistant

Nicolas recently completed his engineering studies to become a general Engineer, focusing on energy issues. As a part of his co-op program, he took the position of research assistant to Professor Martynenko in April of 2015. His goal is to help in designing a new kind of dryer, electrohydrodynamic drying (EHD), based on the effects of high voltage electric field on the drying of food materials, such as apple slices, mushrooms or grapes.

Nicolas recently completed his engineering studies to become a general Engineer, focusing on energy issues. As a part of his co-op program, he took the position of research assistant to Professor Martynenko in April of 2015. His goal is to help in designing a new kind of dryer, electrohydrodynamic drying (EHD), based on the effects of high voltage electric field on the drying of food materials, such as apple slices, mushrooms or grapes.

Gerry Petrash, Industrial Engineering

B. A. (honors French, German minor) Dalhousie University in 1987

Gerry lived in Japan for over twenty years where he owned and operated a private ESL school and was a part-time lecturer at Sapporo International University and Hokusei Gakuen University. He continues to oversee the ESL program for materials engineers at a precision cutting tool factory in Hokkaido, Japan. He returned to Nova Scotia in 2013 to pursue a lifelong interest in science.

Gerry lived in Japan for over twenty years where he owned and operated a private ESL school and was a part-time lecturer at Sapporo International University and Hokusei Gakuen University. He continues to oversee the ESL program for materials engineers at a precision cutting tool factory in Hokkaido, Japan. He returned to Nova Scotia in 2013 to pursue a lifelong interest in science.

Gerry has worked with the Bioprocess Research Engineering Group since the spring of 2014, managing the circuits and imaging labs and providing technical, design and research support to Professor Martynenko and his team of researchers. He is enrolled in the industrial engineering program at Dalhousie University.

Publications

1. BOOKS AND BOOK CHAPTERS:

Martynenko A.I. (2008). Computer Vision System for Ginseng Drying: Remote Sensing, Control and Optimization of Quality in Food Thermal Processing. ADM Verlag, 200 p.

Martynenko A.I. (1999). Modeling of Biological Systems and Processes. 256p. (course notes)

Possudin Yu.I, Martynenko A.I. (1999). Applied Physics and Biophysics. Kyiv: National Agricultural University of Ukraine. 129p.

Martynenko A.I., Muzichenko V.A. (1995). Experimental Design of Biotechnical Systems: Kiev: Institute of Theoretical Physics. 49p.

Martynenko I.I., Martynenko A.I., Girnyk N.L. (1994). Heat and Mass Transfer in Agricultural Technologies. Moscow: Kolos. 194p.

2. REFEREED ARTICLES: Total = 62 (24 published in 2006-2016)

Martynenko A., Chen Y. (2016). Degradation kinetics of total anthocyanins and formation of polymeric color in blueberry hydrothermodynamic (HTD) processing. Journal of Food Engineering 171(1), 44-51.

Wang D., Martynenko A. (2015). Estimation of total, open- and close-pore porosity of apple slices during drying. Drying Technology. In Press

Martynenko A., Zheng W. (2015). Electrohydrodynamic drying of apple slices: Energy and quality aspects. Journal of Food Engineering 168(1), 216-222.

Qui J., Khalloufi S., Martynenko A, Van Dalen J., Schutiser M., Almeida-Rivera C. (2015). Porosity, bulk density and volume reduction during drying: literature review of measurement methods and coefficient determinations. Drying Technology, 33(14), 1681-1699.

Kudra T, Martynenko A. (2015). Energy aspects in electrohydrodynamic drying. Drying Technology 33(13), 1534-1540.

Martynenko A, Kudra T. (2015). Non-isothermal drying of medicinal plants. Drying Technology 33(13), 1550-1539.

Martynenko A, Astatkie T, Satanina V. (2015). Novel hydrothermodynamic food processing technology. Journal of Food Engineering 152(1), 8-16.

Martynenko A. (2014). True, particle and bulk density of shrinkable biomaterials: evaluation from drying experiments. Drying Technology: An International Journal, 32(11), 1319-1325.

Satanina V., Kalt W., Astatkie T., Havard P., & Martynenko A. (2014) Comparison of anthocyanin concentration in blueberries processed using hydrothermodynamic technology and conventional processing technologies. Journal of Food Process Engineering, doi: 10.1111/fpe.12117.

Martynenko A., Janaszek M.A. (2014). Texture changes during drying of apple slices. Drying Technology: An International Journal, 32 (5), 567-577.

Chen Y, Martynenko A. (2013). Computer vision for real-time measurements of shrinkage and color changes in blueberry convective drying. Drying Technology, 31(10): 1114-1123.

Papadopoulos A.P., Yaganza E.S., Hao X, Martynenko A., Ramados M., Saha U.K., Ehret D.I. Khosla S. (2012). Effect of oxygen super-saturated nutrient solutions on greenhouse tomato. Acta Horticulturae 952: 713-720.

MacDonald, M.T., Lada, R.R., Martynenko, A.I., Dorais, M., Peppin, S., Y.Desjardines. (2012). Is There a Relationship between Ethylene Evolution, Ethylene Sensitivity, and Needle Abscission in Root-detached Balsam Fir? Acta Horticulturae 932: 405-412.

Martynenko A.I. (2011). Porosity evaluation from real-time imaging and mass measurements. Food and Bioprocess Technology, 4(3): 417-428.

MacDonald, M.T., Lada, R.R., Martynenko, A.I., Dorais, M., Peppin, S. (2011). Ethylene exposure duration affects postharvest needle abscission in balsam fir (Abies balsamea L.). HortScience 46(2): 260-264.

MacDonald M.T., Lada R.R., Martynenko A.I., Dorais M., Pepin S., Desjardins Y. (2010). Ethylene triggers needle abscission of root-detached balsam fir. Trees, 24(5): 879-886.

Davidson V.J., Martynenko A.I, Parhar N.K., Sidahmed M. and R.B. Brown. (2009). Forced-air drying of ginseng root: pilot-scale control system for three-stage process. Drying Technology, 27: 451-458.

Martynenko A.I. (2008). The system of correlations between moisture, shrinkage, density and porosity. Drying Technology, 26(12): 1496-1499.

Martynenko A.I., Yang S.X., Pan L. (2007). Intelligent computation of moisture content in shrinkable biomaterials Drying Technology, 25(10): 1667-1676.

Martynenko A.I., Yang S.X. (2007). Intelligent control system for thermal processing of biomaterials. IEEE Conference on Networking, Sensing & Control, London, UK, 2007: 93-98.

Martynenko A.I. (2006). Computer-vision system for control of drying processes. Drying Technology, 24(7): 879-888.

Martynenko A.I., Brown R.B., Davidson V.J. (2006). Physical and physiological factors of ginseng root drying. Applied Engineering in Agriculture, 22(4): 571-576.

Martynenko A.I., Yang S.X. (2006). Biologically inspired neural computation of ginseng drying rate. Biosystems Engineering, 95(6): 385-396.

Martynenko A.I. (2006). Evaluation of mass-transfer resistances from drying experiments. Drying Technology, 24(12): 1569-1572.

3. REFEREED CONFERENCE PROCEEDINGS:

Wang D, Martynenko A. (2015). Separate evaluation of open- and closed-pores porosity. 12th International Congress on Engineering and Food (ICEF12), Quebec, Canada, June 14-18, 2015

Martynenko A, Zheng W. (2015). Electrohydrodynamic (EHD) drying technology. 12th International Congress on Engineering and Food (ICEF12), Quebec, Canada, June 14-18, 2015

Martynenko A., Kudra T. (2014). Quality Drying of Medicinal Plants. Proceedings of 19th International Drying Symposium IDS 2014, Lyon, France, August 24-27, 2014.

Kudra T., Martynenko A. (2014). Energy Aspects of Electrohydrodynamic Drying. Proceedings of 19th International Drying Symposium IDS 2014, Lyon, France, August 24-27, 2014.

Martynenko A., Wang D. (2014). Real-Time Porosity Evaluation from Drying Experiments. ASABE Annual International Meeting, Montreal, Canada, July 13-16, 2014.

Martynenko A., Astatkie T. (2014). Hydrothermodynamic Technology for Food Processing. ASABE Annual International Meeting, Montreal, Canada, July 13-16, 2014.

Martynenko A., Kudra T. (2014). Quality Optimization in Convective Drying of Medicinal Plants. ASABE Annual International Meeting, Montreal, Canada, July 13-16, 2014.

Martynenko A., Chen Y. (2013). Real-Time Quality Evaluation in Fruit Drying, using Computer Vision. Proceedings of 2013 CIGR International Symposium on Advanced Food and Quality, China, November 3-7, 2013, Paper #141.

Martynenko A., Satanina V., Astatkie T., Havard P., Kalt W. (2013). Hydrothermodynamic Technology for Fruit Processing: Effects on Food Quality. Proceedings of 2013 CIGR International Symposium on Advanced Food and Quality, China, November 3-7, 2013, Paper #96.

Martynenko A., Chen Y. (2013). Color as a primary indicator of fruit quality in convective drying. Proceedings of International Conference EuroDrying 2013, France, 2-4 October, 2013, 119-120.

Martynenko A., Janaszek M. (2013). Measurement of texture parameters as a function of moisture content in apple convective drying. Proceedings of International Conference EuroDrying 2013, France 2-4 October, 2013, 121-122.

Martynenko A. (2013). True density of shrinkable biomaterials: Evaluation from drying experiments. Proceedings of XXIII Polish Conference on Chemical and Process Engineering, Kolobrzeg, Poland, September 2-6, 2013: 316 (reviewed conference abstract accepted in March 2013).

Martynenko A., Janaszek M. (2013). Texture changes during drying of apple slices. Proceedings of XXIII Polish Conference on Chemical and Process Engineering, Kolobrzeg, Poland, September 2-6, 2013: 317 (reviewed conference abstract accepted in March 2013).

Martynenko A. (2012). Encapsulation of Anthocyanin-Rich Blueberry Powders. Agri-Food and Biotechnological International Symposium. Oaxaca, Mexico, 19-21 September 2012 (keynote speaker).

Martynenko A., Satanina V., Dickson P. (2012). Real-time imaging of blueberry quality in the process of drying. 18th International Drying Symposium IDS 2012, Xyamen, China, November 11-15, 2012 (reviewed conference abstract accepted in July 2012).

Martynenko A. (2012). Linear, radial and volumetric shrinkage of fruit cylinders in convective drying. 18th International Drying Symposium IDS 2012, Xyamen, China, November 11-15, 2012 (reviewed conference abstract accepted in July 2012).

Martynenko A., Sampson D. (2009). Three-dimensional imaging for density and porosity evaluation. Proceeding of 8th World Congress of Chemical Engineering, Montreal, August 23-27, 2009 (available on www.wcce8.org).

Martynenko A. (2009). Food quality optimization in thermal processing. Proceeding of 8th World Congress of Chemical Engineering, Montreal, August 23-27, 2009 (available on www.wcce8.org). (keynote speaker).

Sampson D., Martynenko A. (2009). Three-dimensional (3-D) imaging for real-time volume evaluation, NABEC 2009, Halifax, July 25-29, 2009.

MacDonald M.T., Lada R.R., Martynenko A.I., Dorais M., Pepin S., Desjardins Y. (2009). Ethylene modulates needle abscission in root-detached balsam fir. Horticultural Science, 44: 1142.

Martynenko A., Brown R.B, Davidson V.J. (2004). Physical and physiological effects in ginseng root drying. ASAE/CSAE 2004 Annual International Meeting, Report 043026, 2004.

Contact

Email: alex.martynenko@dal.ca

Phone: (902) 893.6696

Mailing Address:

Department of Engineering

Agricultural Campus

PO Box 550

Truro, NS, B2N 5E3